Below is a comprehensive method statement for GI and PVC conduit installation which can be used for purpose of any project and it can be approved easily by consultants because it covers all aspects of a standard conduit installation method. We have also given

Read Complete Method

This page provides a precise method statement for drainage pipe installation which is useful for any kind of project. Below is list of plant & equipment used for the drainage piping installation work: Measuring tape Tool Box Measuring Tape Hack Saw Spirit

Read Complete Method

1. PURPOSE: This method statement covers the pre-testing and starting up of hot water boilers. 2. SCOPE OF WORKS: To ensure the correct measures are taken to allow a safe and successful start up of the oil fired boilers prior to distributing hot water throughout the hot

Read Complete Method

Cable Tray Inspection & Testing Form

Construction Supervisors to ensure that all ductwork and insulation have been inspected and signed off by the client prior to the installation of diffusers, grilles and louvres to the HVAC ducting system. It is also responsibility of site engineer and supervisor to

Read Complete Method

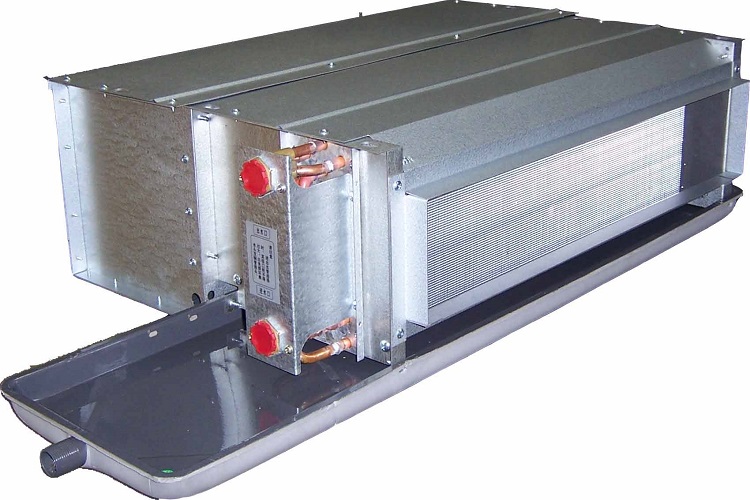

Below is mechanical method statement that is prepared in order to make sure that site installation of all types of Fan Coil Units and Packaged Air Conditioning Units and associated refrigerant pipework is done as per applicable requirements and manufacturer instructions. Procedure

Read Complete Method

Cleaning and flushing of chilled water piping system is very important part of any HVAC project. During installation there are many sources from which debris, dusts and even metallic parts enter the system. Before putting the system in operation cleaning and flushing

Read Complete Method

Procedure For Liter Weight of Clinker The liter weight of clinker is a good measure of burn-ability by calculating the density of the clinker. The size of clinker for liter weight is between 5 & 10 mm. A clinker of density approximately 1100 g/ltr

Read Complete Method