Below is a precise method statement for the installation of sub circuit wiring, which is applicable for any kind of the electrical project.

MEP engineers shall coordinate works as per coordinated drawings developed, in order to ensure that the locations for electrical services are in accordance with approved shop drawings and as per the site coordination requirements.

Future disconnection and relocation provisions shall be done as per the shop drawings which are to be coordinate and approved by the civil project manager & MEP manager and civil construction manager if applicable.

All the wiring material used shall be approved prior to start the wiring installation works.

All materials and documentation relevant to a particular section of works will be checked by the site/project engineer prior to the commencement of work ensuring that these are of the correct type as reviewed by the client.

Before commencement any construction works, pre-inspections will be carried out on all materials prior to them leaving the storage area i.e. quantity, physical damage and brand/make.

Works shall not proceed until an approved shop drawing or detail is issued.

Safe Access to work areas shall be provided and shall be approved by the competent safety person prior to commencement of works as applicable.

Ensure all load schedules are signed and approved by the project consultant engineer prior to proceeding with any wiring works.

Check the installation & approval of distribution board / back box either recessed or surface and termination of all conduits & trunking completed.

Confirm DB reference with load schedule detail.

Make sure that all conduits as per circuits are installed.

Clean distribution boards and make sure all conduits are free from blockage, use of air blowers to clean conduits is helpful.

Wiring and Cabling General Requirements

Building wires and cables are to be installed in conduit, trunking or ducts indoors and in conduit outdoors, unless otherwise shown in the drawings.

Unless otherwise shown on the drawings, final branch circuit wiring is to be run inside trunking or conduits, DC wiring is to be run in separate conduits from AC wiring, and emergency lighting and power circuits are to be run in separate conduits from normal circuits.

BRANCH CIRCUIT WORK originating from light and power panel boards is to be arranged as shown on the drawings.

Loads on various phases of panel boards are to be balanced.

Wiring installation contractor is to ensure that the lighting load and other loads are balanced with a difference of not more than 10% between the phases.

CONTROL CABLES may be fixed to racks, installed directly on cable trays or pulled in conduit and trunking indoors, and in underground ducts or in conduit outdoors.

BUNCHING OF WIRES IN RACEWAYS is to be in accordance with raceway filling factors permitted by the local regulations and project specifications.

BEFORE PULLING WIRES IN CONDUITS check that inside of conduit (and raceway in general) is free of burrs and is dry and clean.

LUBRICANTS are to be used for pulling wire or cable if character of pull would otherwise damage conductors, insulation or jacket. Lubricants are to be approved by the consulting engineer.

PULL CONDUCTORS INTO RACEWAYS simultaneously where more than one is being installed in the same raceway.

SUPPORTS: Cable and wires pulled inside very high conduit risers are to be supported at upper end of risers and at intermediate points by split rubber grommets to relieve any stresses on conductors, where required.

WIRING AT OUTLETS: Leave a slack of at least 200mm at each outlet.

EXTRA LENGTH: At every branch circuit outlet and pull-box, every cable passing through is to be left slack to allow inspection and for connections to be made. Cables terminating in outlet boxes are to be left with at least 250mm extra length for terminations.

JOINTS OR TAPS: In wires and cables, if permitted are to be permanently accessible or made only in boxes or cabinets gutters.

CONNECTORS: for terminating or making T-taps and splices are to be Type A-1on conductors 10mm2 or smaller, Type A-2 for conductors 16 mm2 and larger, type B-1 for branch circuit and fixture wiring.

INSULATING COVERS: are to be applied to prevent exposure of bare cable connections.

SWITCH LEGS for local wall switches are to have distinctive color, selected as complementary to cable color coding used in the project.

TERMINATIONS: Conductors of wires and cables up to 16mm2 are to be tightly twisted and where possible doubled back before being clamped with self taping screws.

Where two or more wires are looped into same terminal these conductors are to be tightly twisted together before inserting into terminals.

In no case is bare conductor to be allowed to project beyond any insulated shrouding or mounting of a line terminal.

Cables size 16mm2 and larger are to be terminated in tunnel lugs with set-screw, or by using bolted or sweated compression connectors.

TAGGING: tag main and feeder cables in pull-boxes, wire ways and wiring gutters of panel boards or distribution cabinets.

Tags are to identify cable or circuit number and conductor size in accordance with the schedules.

Where two or more circuits are run to through a control device, outlet box ceiling junction box, each circuits is to be tagged as guide in making connections.

TIGHTEN: Electrical connectors and terminals including screws and bolts, in accordance with manufacturers published torque-tightening values.

Where manufacturer’s torqueing requirements are not indicated, tighten connectors and terminals to comply with international standards.

Sub Circuit Wiring Method

All wiring of multi-point circuits shall be carried out in a ‘looping-in’ system and no joints and connections are allowed other than those required for the final connection at the DB, ceiling rose, switches, fuses, socket outlets, motors, etc.

Wires shall be drawn in carefully and professionally to avoid damage to the insulation.

All the wires shall be combed as drawing-in of wires operation proceeds.

The Neutral and Earth Continuity Conductor of each circuit shall be drawn along with the Phase conductors of that circuit in individual conduits.

Two circuits of different phase colors cannot be drawn into one conduit.

When pulling/drawing groups of circuits in a common trunking, ensure that individual circuit wires are bunched together with approved cable ties and segregated suitably.

Tape shall not be used to bunch circuit wires.

Sufficient termination length of wires is to be left for the purpose of DB dressing works.

Individual circuits should be marked at the DB end as per the Final Approved Load Schedule.

All wire sizes and phase color should be checked against Final Approved Load Schedules prior to drawing in operations.

3Core Heat Resistant Flexible (105degrees) cables are to be used to make final connections between the ceiling rose and light fitting control gear.

Flexible connection to load points like water heaters, heating Elements / appliances, and other power appliances should be done with 3 cores heat resistant flexible cables of appropriate size.

Ensure that all final load portable appliances are connected through an appropriately rated flex connection outlet installed near the appliance.

Number of wires that can be drawn into a conduit shall not be more than the capacity for that conduit or Trunking and shall comply strictly with the IEE Wiring Regulations regarding capacity of conduits and trunking and space factor.

Earth conductors (ECC) shall be used throughout the installation and the size of these wires should be half the size of the Phase conductor and should be of the same grade and temperature rating of the phase conductors of the same circuit.

GI conduits should not be used to provide earth continuity to the circuits, ECC conductors should be installed with every individual circuit ECC conductors are color coded Yellow/Green.

All the GI conduits and all other metallic containment system should be Earth Bonded separately to integral earth system.

The cross-sectional area of earth conductors shall be in strict accordance with the approved schedule.

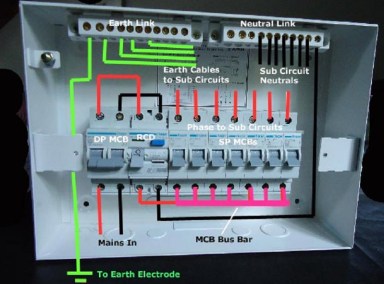

Once all wires of the DB are pulled/drawn in, conduct a check against load schedule and segregate phase, neutral and earth wires.

Install wire marking ferrules and straighten the wires neatly.

Clean the DB Back box, and install the DB Bus bar assembly along with the breakers, ELCB etc., tighten all screws fixing the breakers to the bus bar assembly and torque tighten all screws.

Using an Insulation Tester (Megger) all Cables and wire runs should be individually tested for insulation failure.

Insulation failure to be tested between Phase to Phase, Phase to Neutral, phase to earth, Neutral to Earth.

Continuity tests and Polarity tests to be done before termination of wiring accessories and Final DB Breakers / ELCB.

The readings /measurements are to be recorded on the test reports which are to be signed, dated by the supervisor, Project Engineer and Consultant Engineer.

These Test Reports are to be later stamped and forwarded to local distribution company prior to LV inspections.

Wires / Cables Termination Requirements

Firstly, Gland, earth tag, and terminate the main feeder XLPE/SWA/PVC/Cu cable into the Incomer Device of the DB.

Care is to be taken to allow enough space for installing outgoing wires at both sides of the main bus bar assembly.

(Tip: allow a little excess loop in incomer cable for future maintenance requirements.)

Secondly terminate the ECC Conductors on the ECC earth bar, neatly and bunching the wires in a straight line.

Care should be taken to provide future maintenance access to remove terminated wires.

Next terminate the neutral conductors in the same way.

Then terminate the phase conductors as per Load Schedule order.

There should not be any exposed copper conductor visible after termination.

Overall appearance of the finished wiring installations should be of high quality workmanship standards, to achieve this only experienced Panel board Technicians should be deployed to do this work.

To complete the DB dressing, ensure that the Final Load Schedule is laminated, and fixed in a plastic pouch on the DB Door; all breakers should be identified with a legend sticker fixed in the middle of the breaker assembly.

DB reference identification name plate is to be fixed on the front top of the DB, this Name Tag should be embossed plastic (black background with white colored letters)

Raise inspection request to consultant engineer for the inspection and approval of the electrical wiring installation works.

Inspection & Testing of Wiring Work

Initial insulation testing is done prior to start of DB dressing works as mentioned above.

Final insulation tests, polarity tests, and continuity tests is to be done prior to consultant’s inspection.

Earth Resistance tests should be conducted utilizing the standard procedures and with calibrated and tested professional equipment.

All earth resistance test results should comply with local electrical regulations and project specifications.

Other tests are to be done as per consultant requirements and project specifications.

In process works shall be monitored daily by the Supervisor, Project Engineer and Consultant Engineer for quality of workmanship and installation method against approved layout/shop drawings, approved submittals, project specifications, and prevalent applicable regulations.

All works shall be inspected for conformance to specifications and applicable legal requirements.

Health and Safety Requirements

- TOOL BOX TALK with foremen and workers before starting job.

- Use Personal protective equipment (PPE) as per site requirements.

- All method statements to be approved by the safety team before work commences.

- Obtain electrical work permit when the work involves energized circuits.

- Follow Lock out/Tag out procedure during testing and commissioning.

- Keep suitable fire extinguishers near every DB where work is happening.

- Work on the electrical installations will only be done by qualified and competent persons who will issue certificates on completion of work, which will be retained on site.

- All portable electrical equipment will be tested by qualified persons at yearly intervals in offices, workshops at 6 monthly intervals and on site at 3 monthly intervals, certificates of test will be retained.

- Only electrical equipment, which has been tested and for which certificates of test are in force, will be permitted to use.

- Electrical equipment or supplies shall not be used in such a manner that may cause danger or injury to personnel or property.

- Electrical installations or equipment which may be exposed to mechanical damage, inclement weather or other harmful conditions shall be protected suitably, so as not to cause danger or injury to operatives or other persons.

- In some cases: 110 volt electrical equipment only will be used so far as is practicable on construction or civil engineering sites, unless requirement to use further reduced equipment is specified.

- Where overhead power lines are likely to cause danger, the Area Electricity Authority will be consulted and, if required, ‘shrouds’ fitted or suitable fencing and barriers erected, at least 6m from power lines to prevent access.

- If required to work under or near overhead power lines a permit to work system should be implemented, if necessary.

- Lines to be made DEAD or suitable precautions taken, i.e. barriers/ goal posts.

- Excavators and power tools will not be permitted to be used within 0.5 meter of underground cables, unless a safe system of work is established.

- Use of permits to work may be necessary wherever applicable.

- All work adjacent to overhead or underground electrical supplies will be supervised by a competent person.

- All portable generators will be used in accordance with manufacturer’s instructions.

- 240V cables to be protected and all switch boxes are to be provided with RCD’s.

- Fire extinguishers of an appropriate type e.g. dry power / carbon dioxide shall be available.

- Competent Site Fire Marshal & Wardens should be available all the time on the project site and in specific working areas.

- All electrical testing commissioning should be carried out under a permit to work system by competent persons.

- Manual handling risk assessment of the load and task should be conducted and control measures to be implemented. Method statement to be produced detailing the controls identified by the assessment. If the risks cannot be controlled or reduced to a safe level the operation should not be carried out and a different system/object to be identified for job and always inspect before use.

- Ensure personnel using power tools are trained on proper usage of tools.

- All areas of commissioning to be suitably cordoned off.

- Use only insulated tools for testing of electrical systems.

- Ensure that good house keeping is maintained in the working area.

- Necessary signage for electrical hazards to be placed.

- No unauthorized personnel should be allowed in the testing area.

Use of Step Ladders

- Ladder to be used for access only where allowed.

- Damaged ladder shall be tagged and removed from site.

- Ladder should not be used in horizontal position as platform / runway or as part of scaffold support.

- Ladder shall be placed at an angle of 75o

- When there is a possibility of ladder being struck by moving vehicle / equipment, banks man shall be placed and base to be fenced off.

- One person shall use ladder at a time.

Discover more from Method Statement HQ

Subscribe to get the latest posts sent to your email.